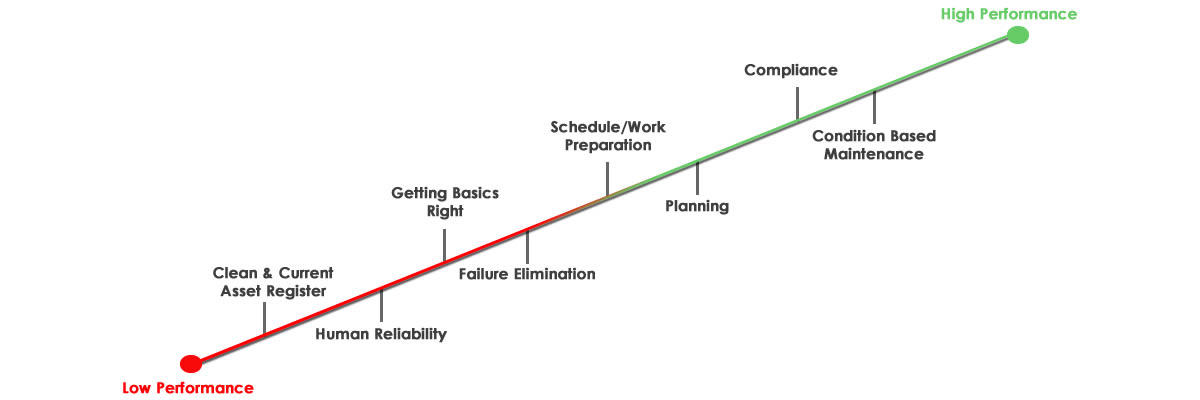

The Reliability Improvement Process (TRIP™)

The reliability of a plant or facility, or how long a period it runs before an unplanned stoppage, determines its performance. Process safety, environmental and cost performance all depend on it. It is thus a pivotal driver, which can be used to make significant business gains. Sustainable improvement requires a systematic and structured approach. M2K have developed ‘The Reliability Improvement Process’ (TRIP™), a stairstep process (illustrated above) that will enable facilities to attain high levels of safety, product quality and production volumes, at the lowest sustainable operating cost.

Route Map for TRIP™

- Up-to-date Asset Register - essential for planning and organising effective maintenance.

- Competent, motivated workforce; high HOTT (Hands-on Tool Time) ratio.

- Failure Elimination and Threats program – Bad Actor Analysis; Pareto; MTO (Manage Threats and Opportunities); RCA / 5Ys.

- Get The Basics Right – equipment ownership, housekeeping, cleaning, lubricating and first line maintenance by operators.

- Robust Planning Process – top performers do 90% PM work.

- Strong WPSE (Work Preparation, Scheduling & Execution) practice; everything in place to do right work at right time in most efficient and effective way.

- High PM Compliance %age – volume of emergent work should be low.

- Condition Based Maintenance – monitoring the health of equipment means detecting warning of a failure and predicting when to intervene.

TRIP™ is a collaborative effort between your asset management staff and us. Generally, all facilities do some things well and from this starting point, we help the client revamp their improvement process. TRIP™ compares local practices with proven best practices, identifies worthwhile improvement opportunities and devises "what to do and how to do it" solutions to exploit these opportunities. M2K have worldwide experience in implementing TRIP™ that will enable you to reach the ranks of top performers.

Click HERE for further detail (.pdf format)

Home